+91 9967303529 / +91 9156095924 | response@servofeeder.in / pcoilhand@gmail.com

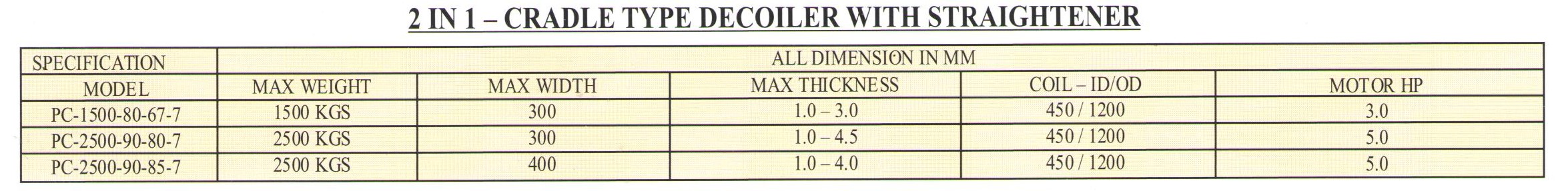

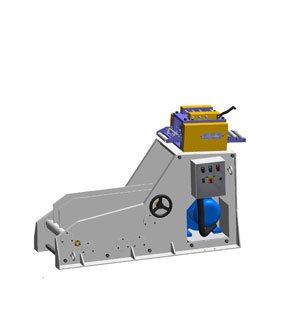

2 In 1 Crade Type Decoiler With Straightener

500 kgs cradle

1500 kgs cradle

2500 kgs cradle

- Central expansion where the coil is placed inside the plates so that it will driven by rollers and gets straight into the straightener head.

- Coil is guided through horizontal rollers which helps to slide the coil easily

- cradle type Decoiler with Straightener comes in Different models.

- Most of the cradles are made for heavy coil handling but in Perfect coil handling equipments we have studied the customer requirement hand had end up with basic 500 kgs coil weight capacity cradle also.

- Straightening rollers are grinded hardened in thermal process with 57 to 58 HRC & hard chrome plated thereafter.

- If the coil thickness is lesser than 1.0 mm then we use Antenna type sensor hence, we the coil thickness gets higher then we use limit arm sensor.

- Geared Motor mounted inside the base is of 2.0 HP Motor, Size 3”, Gear box, Chain Driven given in base model.

- Standard control panel 2.0 Hp used for Single Straightener in base model, VFD control panel is also available on special purposes which helps in speed variation.

- 1 Set of pinch roller & 7/9 Nos of straightening rollers functions straightening of coil material.

- Gang housing given on the top of the straightener for the alignment of straightening rollers up to coil thickness 2.5 mm and individual housing for roller adjustment beyond thickness 2.5 mm along with pneumatic cylinders to put pressure on coil feeding.