+91 9967303529 / +91 9156095924 | response@servofeeder.in / pcoilhand@gmail.com

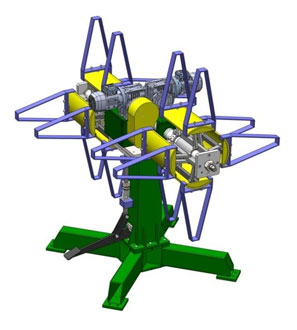

Twin Type Motorized Decoiler With Straightener

- Twin Type Motorized Decoiler With Straightener

- Special model of higher capacity are available as per customer requirement

- In twin type decoiler with straightener the coil can placed on both side at the same time to consume coil loading time. Straightener head is attached on the body. One coil at a time can place into straightener. Once the coil get finished, with the help of pedal the operator can easily roates the head of decoiler and use the second coil to run production.

- The coil is placed on drums of decoiler, this flexible drums helps the coil to get fixed in mandrel and makes it easy to decoil and feed further.

- As per the coil inner diameter expansions, the jaw expandables are made so that the coil gets loaded on decoiler easily

- The total fabricated structure is made & assembled in our factory.

- 500 Kgs decoiler consist narrow width guide rings if required, from 1000 kgs to further model we use width guides.

- Mandrel is of link type adjustable structure in which the drum is one side mounted which makes a user easy to expand the jaw in the case of narrow width guide rings & link type expansion in our standard model.

- Front and back horizontal guide supports for coil.

- Suitable models for different coil thickness and width from minimum 1 mm thickness.

- Straightening rollers are grinded hardened in thermal process with 57 to 58 HRC & hard chrome plated thereafter.

- If the coil thickness is lesser than 1.0 mm then we use Antenna type sensor hence, we the coil thickness gets higher then we use limit arm sensor.

- Geared Motor mounted inside the base is of 2.0 HP Motor, Size 3”, Gear box, Chain Driven given in base model.

- Standard control panel 2.0 Hp used for Single Straightener in base model, VFD control panel is also available on special purposes which helps in speed variation.

- 1 Set of pinch roller & 7/9 Nos of straightening rollers functions straightening of coil material. For higher thickness and coil width - pneumatic pinch roller is used which keeps pressure of coil through pneumatic cylinders.

- Gang housing given on the top of the straightener for the alignment of straightening rollers up to coil thickness 2.5 mm and individual housing for roller adjustment beyond thickness 2.5 mm

MD 500 kgs twin

MD 1000 kgs twin