+91 9967303529 / +91 9156095924 | response@servofeeder.in / pcoilhand@gmail.com

Manufacturer of Decoiler with Straighteners

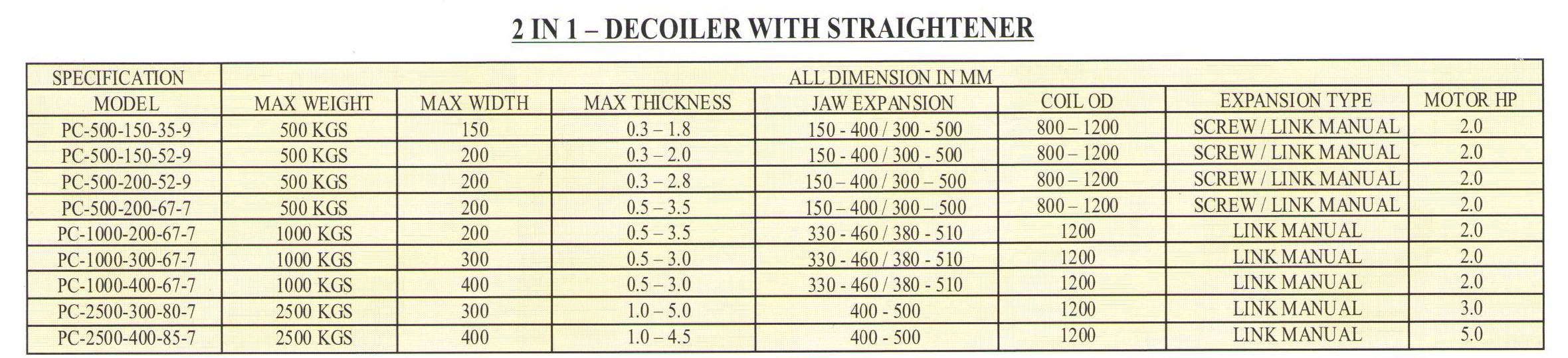

2 in 1 Decoiler With Straighteners

1500 Kgs Compact

500 Kgs Compact

500 kgs Compact with crane Assembly

500 Kgs Compact

1000 kgs Compact

- Unleashing Precision with Decoilers and Straighteners Perfect Coil Handling Equipments introduces a revolutionary solution to streamline your coil processing Decoilers with Straighteners. Our integrated systems are meticulously designed to provide unparalleled precision and efficiency in coil handling, ensuring optimal performance for a wide range of materials and industries.

- Three jaws mandrel where the coil is placed with the guide ring so that it gets straight into the straightener head.

- Star type mandrel specially made for 200 & 500 Kg coils.

- 500 Kgs Decoiler with Straightener comes in Different models.

- Straightening rollers are grinded hardened in thermal process with 57 to 58 HRC & hard chrome plated thereafter.

- If the coil thickness is lesser than 1.0 mm then we use Antenna type sensor hence, we the coil thickness gets higher then we use limit arm sensor.

- Geared Motor mounted inside the base is of 2.0 HP Motor, Size 3, Gear box, Chain Driven.

- Standard control panel 2.0 Hp used for Decoiler and Straightener, VFD control panel is also available on special purposes which helps in speed variation.

- 1 Set of pinch roller & 7/9 Nos of straightening rollers functions straightening of coil material.

- Gang housing given on the top of the straightener for the alignment of straightening rollers up to coil thickness 2.5 mm and individual housing for roller adjustment beyond thickness 2.5 mm.

Purpose and Functionality:

- Decoiling: The primary function of the decoiler component is to unwind and dispense the coiled material in a controlled manner. This is crucial for the subsequent manufacturing processes.

- Straightening: The integrated straighteners ensure that the material is straightened before it progresses to downstream operations, eliminating any distortions or irregularities.

- Material Compatibility: Decoilers with Straighteners are commonly used for materials such as metal strips and wires. This includes various metals like steel, aluminum, copper, and others.

Adjustability:

- Straightening Parameters: The system allows for the adjustment of straightening parameters to accommodate different material types, sizes, and thicknesses.

- Coil Handling Settings: Users can customize the settings for coil handling, ensuring optimal performance for diverse applications.

- Adjustability and Customization: Tailor the settings of our integrated systems to meet your specific requirements. Adjust the straightening parameters and coil handling settings to achieve optimal results for different materials and applications.

- Tailoring to Specific Needs: Manufacturers understand that different industries have unique requirements. Decoilers with Straighteners often come with customization options, allowing users to tailor the equipment to their specific needs.

Integration:

- Seamless Integration: The integration of decoiling and straightening processes into a single system ensures a seamless workflow. This integration reduces the need for additional equipment and optimizes floor space.

Our Decoilers with Straighteners seamlessly combine two critical processes into a single, integrated solution. Experience a smooth transition from coil unwinding to material straightening, optimizing your production line efficiency.

Versatility:

- Wide Range of Applications: Decoilers with Straighteners are versatile and find applications in various industries, including metal forming and stamping, automotive manufacturing, electronics, aerospace, and more. Material Versatility: Whether you're working with metal, or other coiled materials, our Decoilers with Straighteners are designed to handle a variety of materials, sizes, and thicknesses. Enjoy the flexibility needed for diverse applications.

User-Friendly Features:

- Precision Uncoiling: Benefit from the precision of our decoilers, ensuring controlled unwinding of coils. The integration of straighteners guarantees that materials are flawlessly prepared for subsequent manufacturing processes.

- Intuitive Interface: Equipped with a user-friendly interface, the system is designed for easy operation and quick setup, minimizing downtime and enhancing overall productivity. Our machines are equipped with an intuitive interface for easy operation and setup. Reduce downtime and enhance productivity with user-friendly controls that allow for quick adjustment

Why Choose Perfect Coil Handling Equipments?

- Efficiency Redefined: Our Decoilers with Straighteners redefine efficiency by combining two essential processes in one seamlessly integrated system.

- Optimized Production Line:By combining decoiling and straightening functions, the system contributes to an optimized production line, reducing the need for multiple machines and minimizing material handling time.

- Customization ExpertisePerfect Coil Handling Equipments understands that each industry has unique requirements. Benefit from our customization options to tailor our systems to your specific needs.

- Nationall Recognition:Our reputation spans the nation, with industries all over trusting Perfect Coil Handling Equipments for superior coil handling solutions.

- Responsive Technical Support: Our dedicated technical support team is committed to providing prompt assistance, ensuring uninterrupted operations and peace of mind.