+91 9967303529 / +91 9156095924 | response@servofeeder.in / pcoilhand@gmail.com

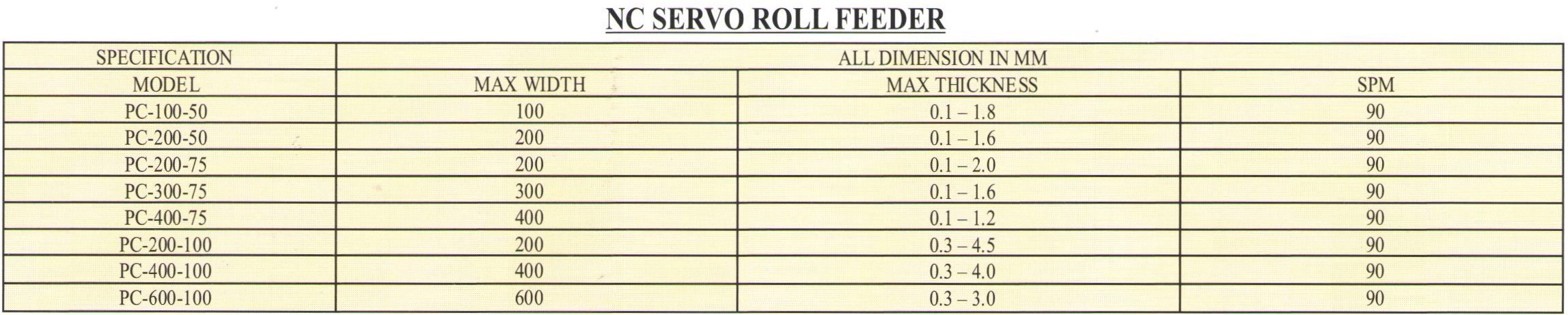

Manufacturer of NC Servo Roll Feeders

- Perfect Coil Handling Equipments: Precision Unleashed with NC Servo Roll Feeders

Welcome to Perfect Coil Handling Equipments, where innovation meets precision in the world of coil processing. Our NC Servo Roll Feeders stand as a testament to our commitment to excellence, offering cutting-edge solutions to streamline your metalworking and stamping operations.

NC Servo Roll Feeders are advanced feeding solutions designed to provide precise and customizable material feeding in metalworking, stamping, and coil processing applications. Perfect Coil Handling Equipments offers state-of-the-art NC Servo Roll Feeders, delivering a range of features to enhance efficiency and accuracy in your production processes. - NC Servo has caliber to perform nonstop functions without failing.

- Rollers up down function with the help of Pneumatic cylinder.

- Ratchet spanner assembled at the bottom for height adjustments of feeder.

- Festo make FRL to control the air pressure with the help of flow control valve.

- Cascade rollers made of steel to feed the coil having conventional loop.

- Vertical rollers as width guide in frontside and backside of roll feeder which is hardened & grinded for better service life.

- Helical Gears for rollers are hardened and grinded on teeth which gives accurate feeding accuracy.

- Rollers are made of solid steel, Hardened with thermal treatment HRC 55/58, Grind & Hard chrome plated after.

- Total electric servo package imported from Mitsubishi Electric (Japan).

- Mitsubishi Make timing belt from servo motor to rollers.

- Imported Coupling from Italy MAV locking assembly to servo motor so the precision can maintain high accuracy of feeding length 0.02 mm.

- The system can store up to 99 Programs.

- Setting of length gets easy through HMI in which speed variation can adjustable.

- Feed before press function is inbuild for Pneumatic/Hydraulic shear cut to length machines.

- Anti-Back Stopper model comes with extra roller which keeps continues pressure on coil material and feed only in forward direction which helps spring steel material to install the coil easily.

Key Features:

- High-Precision Feeding: Our NC Servo Roll Feeders provide unparalleled accuracy in material feeding. Experience precise control over the feeding process, ensuring uniformity and consistency in every operation.

NC Servo Technology:

- Versatility in Material Handling: Perfect Coil Handling Equipments' NC Servo Roll Feeders are designed to handle a wide range of materials, from delicate foils to robust metal sheets. The versatility of our feeders makes them suitable for diverse applications in the metalworking industry.

- Programmable Feeding Parameters: Tailor the feeding parameters to your specific requirements with ease. Our NC Servo Roll Feeders come with programmable settings, allowing you to adjust feeding length, speed, and other parameters for different materials and processes.

- Seamless Integration: Integrating seamlessly into your existing production line, our feeders enhance overall workflow efficiency. Whether you're in automotive manufacturing, electronics, or any other industry, our feeders adapt to your unique needs.

Applications & Industries We Serve:

- Metal Forming and Stamping: Ideal for precision feeding in metal stamping processes, ensuring accurate and consistent results.

- Automotive Manufacturing:Enhances efficiency in feeding materials for automotive parts manufacturing, contributing to high-quality production.

- Electronics and Electrical Industries: Well-suited for applications in electronics, providing precision in material feeding for electronic components.

- Aerospace and Defense: Critical for accurate feeding in the production of components for the aerospace and defense industries.

- Renewable Energy: Contributes to precision in material handling for the production of components in the renewable energy sector.

- Medical Device Manufacturing: Meets the stringent requirements of precision feeding in the production of medical devices.

Why Choose Perfect Coil Handling Equipments for NC Servo Roll Feeders?

Advantages of Choosing Perfect Coil Handling Equipments:

- Innovation at its Core: Our NC Servo Roll Feeders embody the latest advancements in technology, ensuring you stay ahead in the competitive landscape. Customization Expertise: We understand that each industry has distinct requirements. Benefit from our customization options, tailoring our feeders to seamlessly integrate with your processes.

- National Recognition:Perfect Coil Handling Equipments is nationally recognized for delivering high-quality, reliable coil handling solutions, earning the trust of industries all over india.

- Responsive Technical Support: Our dedicated technical support team is ready to assist you, ensuring uninterrupted operations and providing peace of mind.